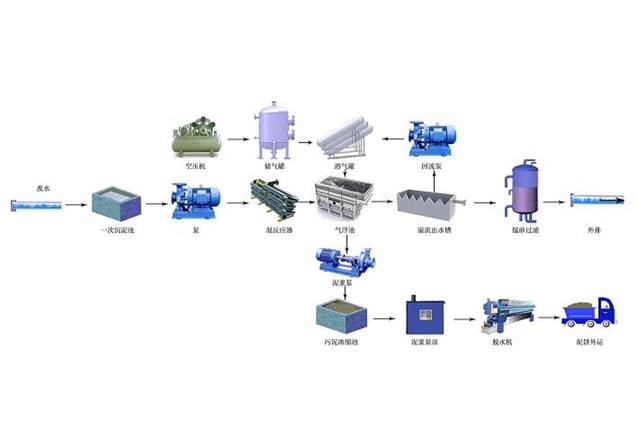

Hot rolling wastewater in iron and steel industry DAF (dissolved air flotation) pretreatment technology is an improved form for traditional three-stage process [rotational flow (primary sedimentation) →laminar flow (secondary sedimentation and oil separator)

→ mechanical filtration (mechanical de-oiling)] and replaces the secondary sedimentation basin of traditional processing method with coagulation + dissolved air flotation.

This method adapts to hot rolling direct cooling wastewater treatment with stricter water quality requirement after treatment, or poor water quality for raw water and mainly

control pollutant in the waste water, such as oils, iron and SS.

Advanced technology

◆ having obtained national invention patent, patent name: pressure dissolved air flotation system (patent No. ZL 2006 10112436);

◆ Stable operation: anti-blocking releaser designed according to different water quality can ensure to generate very uniform fine flotation bubble suited to process object,

is featured with self-cleaning, non-choking and antiseptic performance and does not need any special commissioning and maintenance during the operation;

◆ High-efficiency dissolved device is truly “full automatic high-efficiency” treatment system, with unique high-efficiency dissolved design, without inner packing, small footprint,

less maintenance, more than 99% dissolved efficiency, up to 99% out-gassing rate, self-control system and simple installation and maintenance.

Process principle

The main equipment for Pretreatment system includes primary sedimentation basin, coagulation-reactor (or reaction tank), floatation tank, aeration tank, filter,

sludge thickener and other supporting facilities and replaces secondary sedimentation tank of traditional processing method with coagulation + dissolved air floatation DAF.

It is adhered to contamination particles and grease through the water to inject a large number of micro bubbles and separates solid and liquid by buoyancy rising up to water surface,

but dense and heavy contamination particles subside and fall into bottom of the pool.

Performance index

Taking 1000m3/h hot rolling wastewater processing capacity system as an example: technical index: pollutant content SS≤20mg/L, oil ≤5mg/L;

economic index: floor area 1000~3000m2 and with 2~2.5 million Yuan operation and maintenance cost per year;

Core unit

Core technology for hot rolling waste water pretreatment of iron and steel industry is DAF basin. Its main performance parameters are as followings:

◆designed circulation rate is 15~30%, surface loading is 2.5m/m h;

◆dissolved inlet water pressure is ≥0.6MPa; ◆the diameter for releasing bubble of releaser is 30~50μm and separation efficiency between suspended solids and oils is ≥95%.

Application fields

◆Hot rolling direct cooling wastewater;

◆ hot rolling wastewater, with specific gravity close to that of water, high water temperature and containing oil and suspended solids