High-efficiency floating device is one of core products of our company, boasting one patent for invention and four patents for utility models. It is used for high-efficiency solid-liquid or liquid -liquid separation in wastewater treatment field. At present, there are near 1900 Andmir dissolved air flotation (ADAF) devices running in various industries including petroleum, petrifaction, electricity, metallurgy and food around the world.

The research & development center of Andmir Dissolved Air Flotation is located in America. In order to better serve Asia, especially customers in China, ADAF began to manufacture and sell products in Liaoning of China in 2003, and jointly established Liaoning Waffer-Andmir Environmental Protection Equipment Co., Ltd. In China, it has produced and sold near 200 fourth-generation air floatation devices. In 2010, products upgraded into the fifth-generation with smaller land occupation and stronger handling capacity, which are suitable for place which owns space but lack of area, and able to meet demands of different users in accordance with their requirements.

Technical features

◆ Unique high-efficiency tubular reactor make drug combination better, improving efficiency of water treatment while saving water treatment agent;

◆ Flotation machine is installed with sloping panel inside which can make floc comes up with second flocculation reaction in the process of internal flotation, increasing size of granular and improve separation efficiency;

◆ Dissolved air pressure can reach 0.6Mpa, increasing dissolved air capacity;

◆ Owning to special structure design, integration degree of dissolved air flotation (ADAF) is high with compact structure and small floor space.

Technical principles

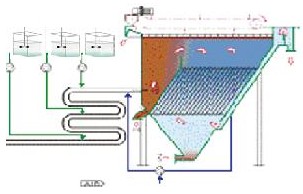

Working principle of dissolved air flotation (ADAF): sewage enters dissolved air floatation machine via tubular reactor, and mix with dissolved air water. In pipe chute dissolved air floatation tank, sewage runs out off air floatation tank through special passageway after sloping-panel separation. Floc attached to minute bubbles floats upward to surface of liquid after separating with water via sloping panel installed in cavity of flotation machine, and then floc is blew off by automatic scraping machine. Sediments in the bottom of flotation machine are blew to blow-down valve by bottom scraping machine for discharging. The emerged part of flotation machine conducts recirculation via circulating pump. Circulating water fast mixes with compressed air after being ripped into leaning dissolved air tank and then becomes dissolved air water.

Device constitution

High-efficiency floating device (ADAF) consists of sloping-panel dissolved air floatation, tubular reactor, automatic control system, dissolved air tank and dissolved air pump.

Performance index

◆ Design circulation rate: 20%

◆ Surface loading: 2.5m/m.h

◆ Dissolved gas pressure: 0.6MPa

◆ Intake pressure of dissolved gas : 0.65MPa

◆ Diameter of bubble released by releaser: 10~50μm

◆ Separation efficiency of suspended solids and oils & fats:≥95%

◆ Handling capacity: 0.5m/h-1200m/h

Application fields

◆ Oil wastewater treatment in petroleum refining and storage & transportation industry;

◆ Emulsified oil removal treatment of produced water in oil-gas field.

◆ Wastewater treatment in coal and metallurgy processing industry;

◆ Oily wastewater treatment in food processing and d