Air Floatation Equipment

Your current location:Home / Productions / Air Floatation Equipment

Dissolved air flotation device

Dissolved air flotation device is one of core products of our company, used for high-efficiency solid-liquid or liquid -liquid separation in wastewater treatment field, which is extensively applied in various industries including petroleum, petrifaction, electricity, metallurgy and food. The device occupies small floor space, which are suitable for place which owns space but lack of area, and able to meet demands of different users in accordance with their requirements.

Working principle:

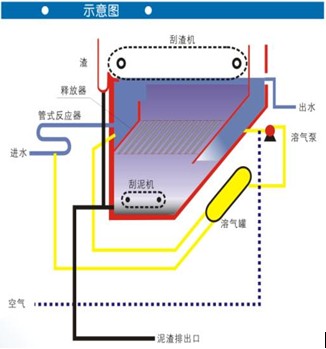

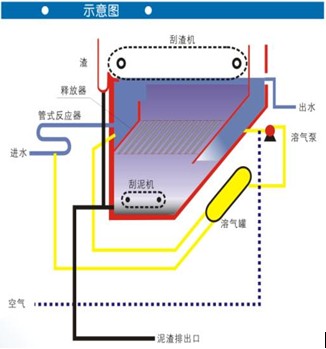

After entering tubular reactor, sewage is respectively added with coagulant and flocculant and fully conducts mixing reaction with sewage in pipeline, then enters dissolved air floatation and mixes with dissolved air water. Floc attached to minute bubbles floats upward to surface of flotation machine after separating with water via sloping panel installed in cavity of flotation machine, and then floc is blew off by automatic scraping machine. Sediments in the bottom of flotation machine are blown to blow-down valve by bottom scraping machine for discharging. Effluent spills over flotation machine via specially-designed passageway. The emerged part of flotation machine conducts recirculation (circulation rate is designed as about 20%) via circulating pump. Adding air (or nitrogen) in entry end of dissolved air pump, it fast mixes with return water till saturation of dissolution. Superfluous air will automatically discharged by relief valve in a bid to keep certain liquid level of dissolved air in mother pipe. Advanced anti-blocking releaser is installed in the bottom of flotation machine. Pressure water of dissolved air uniformly releases bubble via releaser.

Product features:

• Unique structure design guarantees that water flow in flotation machine is in complete laminar condition with surface load less than 2.5m3/m2h, greatly improving separation efficiency;

• Flotation machine is installed with sloping panel inside which can make floc comes up with second flocculation reaction in the process of internal flotation, increasing size of granular and improve separation efficiency;

• Anti-blocking releaser designed in allusion to different water quality can guarantee production of flotation bubbles which are extremely well-distributed, small and suitable for treatment;

• Unique inclined-jar high-pressure dissolved air technology exempts from large-volume dissolved air tank. Dissolved air pressure can reach 0.6Mpa and dissolved air capacity is large, which strengthens the ability of air floatation to holding dirt, able to treat sewage with large oil content and high suspended matter concentration;

• Owning to special structure design, integration degree of sloping-panel dissolved air flotation (ADAF) is high with compact structure and small floor space.

• Able to remove oil and suspended matter with high separation efficiency.

Air floatation support equipment PFR tubular reactor

Working principle:

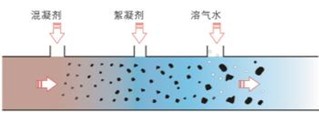

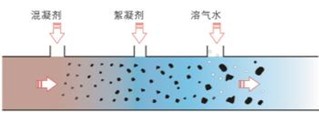

PFR tubular reactor consists of three specially-designed mixing pipelines which are respectively added with coagulant, flocculant and dissolved air bubble. Optimized coagulate effect will be reached via designing and controlling mixing energy and time of every pipe section.

PFR tubular reactor is extensively used in various sewage treatment projects, applied to remove oil and suspended solids, COD, BOD in wastewater. The new-type tubular reactor supporting the use of ADAF can greatly improve separation efficiency of air floatation machine.

Product features:

• Because mixing energy and time in pipeline is easy to control and ensure homogeneous mixing and stable coagulation and flocculoreaction, it is able to generate uniform floccules;

• Because dissolved air bubble is added in the pipe section, bubble can enter the internal of floc via combination;

• Because chemical feeding point is in the middle of pipe section, it is able to decrease consumption of water treatment agent in to the minimum.

Application scope :

• Produced water treatment of oil-gas filed in oil exploitation industry

• Oily wastewater treatment in petroleum refining and storage & transportation industries

• Dust extraction & water separation treatment in power industry

• Solid-contained wastewater treatment in coal and metal processing industries

• Wastewater treatment in printing & dyeing, papermaking and textile industries

• Oily wastewater treatment in food processing and dairy industries