Filtration Equipment

Your current location:Home / Productions / Filtration Equipment

Ultrafiltration membrane filtration complete equipment

Ultrafiltration membrane separation technology boasts features including low effluent suspended solid and removing bacteria and virus, able to greatly improve quality of recycled water, which is also an ideal pretreatment technology for reverse osmosis. With progress of ultrafiltration membrane technology and reduction of cost, ultrafiltration membrane is the first choice for reuse of recycled water. After long-time engineering practice, by means of optimizing operation technology and chemical cleaning technology of membrane, our company successfully solve pollution problem of membrane in wastewater treatment, realizing long-term stable operation of ultrafiltration device. Ultrafiltration membrane device developed by our company includes hollow fiber ultrafiltration membrane device, tubular membrane ultrafiltration device and ceramic membrane ultrafiltration device and so on. Complete ultrafiltration membrane device can be customized in accordance with demand of customer via providing systematic complete design scheme.

Technical features

◆ In allusion to different wastewater, select pointed anti-pollution membrane element via long-term wastewater reuse engineering practice;

◆ Adopt proprietary operation technology and chemical cleaning technology, able to effectively remit membrane pollution and recover membrane flux on line;

◆ Equipped with perfect chemical cleaning unit, dosing unit and automatic control system, is a relatively independent and complete continuous operation system;

◆ Provided with local control cabinet, automatically gathering and store operation data; operation and chemical cleaning realize procedure control; operation parameter can reset immediately in the screen in accordance with actual condition; workload of operation and maintenance is small;

◆ By means of communication interface, able to communicate with DCS center control system of water treatment factory, realizing centralized monitoring;

◆Prying-piece design, small workload of site installation.

Working principle

Ultrafiltration sparation belongs to sieving procedure, taking ultrafiltration membrane as filtering medium and pressure difference of membrane sides; when wastewater flows past membrane surface, water and micromolecule substance pass membrane and substances larger than bore dimeter of membrane are entrapped and concentrated, realizing purification in allusion to polluted water. In order to alleviating membrane pollution, membrane operation procedure generally needs to conduct regular backwashing or concentrated water untangling, as well as other auxiliary technology measures for alleviating membrane pollution. After membrane runs for a certain time, membrane flux descends, it is required to conduct chemical washing and recover membrane flux in allusion membrane.

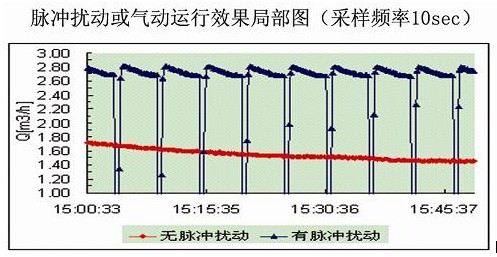

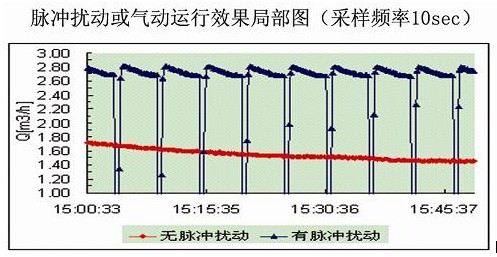

In allusion to hollow fiber ultrafiltration membrane device and tubular membrane ultrafiltration device, our company adopts proprietary pneumatic operation mode, and sets up periodic automatic cleaning procedure; in allusion to ceramic membrane ultrafiltration device, our company adopts periodic impulsive disturbance to operate, effectively lowering pollution rate of membrane.

Device constitution

Standard complete membrane device consists of ultrafiltration membrane element, membrane tubing, membrane support, automatic control instrument and valve, water deliver pump, backwashing pump, chemical cleaning tank, cleaning pump, automatic control cabinet and relevant control software.

Performance index

Treatment scale of unit set membrane device is 1~200m/h, bore diameter of membrane separation is 0.01~0.03μm, suspended solid of membrane effluent is smaller than 1mg/L, median particle diameter of suspended solid is smaller than 0.8μm.

Application area

◆Water treatment reuse in various industries.

◆Anti-osmosis pretreatment project.

◆Oil extraction wastewater precise processing project of low-permeability oilfield.

◆Cold rolling emulsion and concentrated alkaline oily wastewater treatment project.

◆Extraction of useful substance in industries including food processing, biological fermentation and pharmacy.

◆Recovery of wastewater including rubbish penetrating liquid , papermaking black liquid and printing and dyeing ink as well as useful substance