Ion Exchange

Your current location:Home / Productions / Ion Exchange

Ion exchanger

Ion exchange means to adopt ion exchanger so as to make regular reversible exchange with equivalent substance amount of exchangeable ions between exchanger and water solution, while structure of ion exchanger shall not be substantially changed. Ion exchange technology has been widely applied into water treatment industry, such as water softening, water desalting, high purity water preparation, industrial sewage treatment, heavy metal and precious metal recovery etc.

Working principle

Ion exchange and softening technology is the ion exchange device inside exchange container with cation exchange resin filled in. Its full name is cation exchange column which is called softening bed for short. Ion exchange and softening object of water is hard minerals and it is the process that calcium ion and magnesium ion are exchanged or replaced by sodion. Softener make the hard minerals calcium and magnesium dissolved in water be exchanged by sodium in soft mineral on exchanger resin. All those three kinds of minerals are named as positively charged ion of cation.

Inside softening bed, water with hard minerals passes through exchange resin to take ion exchange reaction. The softening bed is installed with millions of fine polystyrene/ divinylbenzene plastic balls, which have many exchange positions for negative charge that can attract positive ion. When resin is at regeneration status, those exchange position for negative ion shall be taken by positively charged sodion. When calcium and magnesium ions pass through storage tank, they shall contact with little resin balls to replace sodion from the exchange position so to be removed.

Characteristics of product

◆There are two kinds of softening device, co-current regeneration and counter-current regeneration;

◆Strong acid cation exchange resin could be used for treating water and regenerate salt;

◆Weak acid cation exchange resin with large hole could be used for treating sewage; regenerate salt and transit alkali;

◆Long work cycle;

◆Manual and self-automatic control can be achieved;

◆Tank and pipe are all steel-lining rubber;

◆All pipes are mounted on ground to prevent corrosion and layout is in alignment;

◆First stage and second stage can mutually be changed over so as to get adapted to change of flow and reduce consumption of resin;

◆Pry block can be divided into two kinds: indoor and outdoor types which can be freely chosen.

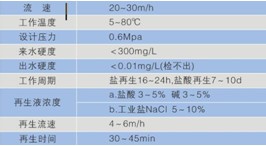

Specification

Application scope

It is always applied in front of reverse osmosis device so as to extend the time of and protect reverse osmosis membrane system. It can also be set in front of electro-deionization device so as to make the quality of water entering into electro-deionization device meet requirement and prevent membrane caking of electro-deionization and prevent influence on quality of outlet water. Besides, it can be applied in water replenishing of low-voltage boiler and water consumption occasions in chemical, power generation and paper making industries etc, so as to remove hardness of water.