Vessel® Micropressure high-efficiency degreaser is a oil-water separation equipment used for industrial wastewater treatment and developed in allusion to working condition which needs to isolates sewage from ambient air. Wastewater disposed by the product realize oil-water separation in closed system under a certain micro-positive pressure. Wastewater strictly separates with environment, avoiding that flammable and combustible matter or toxic and harmful substance contained in wastewater spread to neighboring environment and dissolved oxygen content of wastewater increase.

Product features

◆Treating process realize closeness, system maintain a certain pressure during operation, which can avoid that ambient air enters system and hazardous gas in wastewater pollutes environment.

◆Unique structure design guarantees that water flow in equipment is in the full laminar condition, greatly improving separation efficiency;

◆Inclined pipe installed in cavity of equipment can make oil drop comes with coalescence reaction, increasing size of granular and improving separation efficiency;

◆Proprietary anti-blocking releaser designed in allusion to different water quality can guarantee production of flotation bubbles which are extremely well-distributed, small and suitable for treatment;

◆Unique inclined-tank high-pressure dissolved air technology with small volume of dissolved air tank, large dissolved air capacity and strong ability of bubble to hold dirt, able to handle wastewater with large oil content.

◆Integration tubular reactor makes bubble contact with and adhere to oil drop of wastewater in advance; and mixing energy and time is easy to control. Uniform mixing creates more opportunities for adherence between bubble and oil drop; without no need for mixing agitator, low energy consumption.

◆Owning to special structure design, integration degree of micropressure high-efficiency degreaser is high with compact structure and small floor space.

Working principle

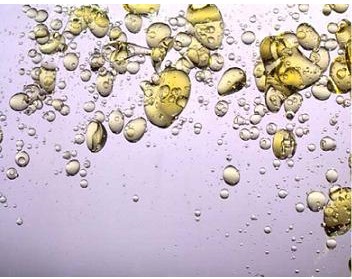

Wastewater to be disposed firstly enters tubular reaction zone of micropressure high-efficiency degreaser, conduct first premix with dissolved air water, then enters main body reaction zone of micropressure high-efficiency degreaser and conduct second mix with dissolved air water, making micro-bubble released by dissolved air water fully mix with wastewater. Oil drops attached to small bubble form air floating matter. Air floating matter directly rise to surface of wastewater under the influence of large buoyancy force. Air floating matters which cannot directly rise up flow with wastewater, comes up with adherence and agglomeration with inclined pipe under the effect of shallow-pond principle of inclined-pipe separation region, forming large oil drop or that air floating matter rise to water surface which make oil separate from water again and wastewater is fully purified. Emersed part quickly mixes with air and dissolves unitl saturation via dissolved air system, and release uniform bubble to mix with inflow again via proprietary anti-blocking releaser. Oil layer floating on the surface of wastewater are discharge regularly via overflow launder. Suspended solids of wastewater form sediments in the bottom of tank. The sediments are discharged by mud pipe in the bottom. Disposed water is discharged from equipment body through outlet passageway.

Device constitution

Device mainly consists of tank, pump, dissolved air tank, air supply system, adding medicine system, dissolved air releasing system and control unit.

Performance index

◆ Dissolved gas source:choose nitrogen, natural gas or air in accordance with actual working condition.

◆ Handling capacity of unit set: 50~300m/h

◆ Working pressure 0.03~0.05MPa

◆ Oil removal efficiency ≥90% (medicate)

◆ Reflux ration of dissolved gas ≤20~25%

Application scope

◆ Oil extraction wastewater treatment in offshore oil platform;

◆ Oilfield produced water treatment which land oil field needs to isolate oxygen high salinity and high corrosion;

◆ Oily wastewater treatment which petrochemical industry needs to isolate oxygen;

◆ Airtight oily wastewater treatment for industrial wastewater.