It is a kind of solid-liquid separation device, which is widely applied throughout sludge treatment industry at present due to its advantages of high separation efficiency, wide adaptability and reliable operation etc. Its performance has been affirmed by the whole industry. Our company has over ten years’ experiences on design, manufacture, installation, operation and maintenance of filter press; we have advanced sludge dewatering process and advanced PLC control technology in the world; we have technology of high-efficient sludge dewatering system. Separation efficiency of the device is high with high automatic control degree, low operation cost, low operation failure, small labor strength and obvious clean environment etc. it is a kind of environmental protection, energy-saving and high efficient sludge dewatering device.

Specification

• Specification:315, 400, 500, 630, 800, 1000, 1250 and1500 types

• Filtering area:0.5m—500m

• Structure of filter plate: box type, sheet-frame type and membrane type

• Outflow way of filtrate: flow in open air, underflow, washable and un-washable

• Way of compact: manual compact, mechanical compact and hydraulic compact

• Filter pressure: 0.2MPa—2.0MPa

Working principle

As major equipment of the device, filter press is a kind of intermittent solid-liquid separation device with filtering chamber formed by arrangement of filter plate. Material liquid shall be transferred into each filter chamber by material-handling pump and it shall pass through filtering medium under pressure of material-handling pump. The filtering medium shall stop solid inside the filter chamber and drain the liquid out. There are many kinds of materials and types of filter plate for selection so as to meet requirements for separating various sludge according to characteristics of sludge. Water resistant device is a unit of anti-parallel link mechanism with beautiful appearance and easy operation. Solid material conveyor adopts totally-enclosed shaftless screw conveyor which can completely transfer all materials and keep clean environment. Main control system adopts foreign PLC system so as to fulfill automatic switch and operation between main machine and auxiliary machine.

Composition of the device

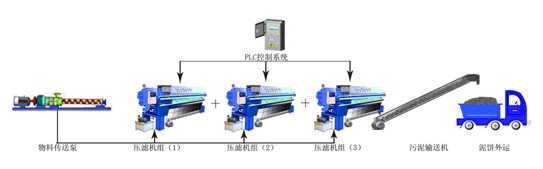

Sludge filter pressing and treatment device comprise material-handling pump, filter press, water resistant device, sludge conveyor and PLC control system etc. Technical

Technical features

It takes pressure filtration principle, integrated type of micro-current control hydraulic drive technology and automatic program control to fulfill the operation of closely separation and integrated communication control. Back washing, air drying and membrane-pressure drying functions can be made according to demand of customers so as to maximally reduce moisture of filter cake and completely wash out impurities in filter cake during back washing period. Solid content in filtrate is low (not more than 0.03g/l) and back washing water can be recycled so as to achieve closed cycle. It is the ideal environmental protective device. Detailed technical features are listed as follows:

Hydraulic system adopts servo variable pump to supply oil and it has high efficiency and low energy consumption;

The control system adopts PLC system and it is easy to be fulfilled with easy operation;

Manual control and automatic control can be freely switched under any state and it has easy operation and reliable action;

Strengthen once compression molding of patent polypropylene filter plate and it has high strength and long service life without crack;

Its integrated configuration can effectively guarantee low moisture in filter cake;

Transportation of material is smooth without adherence on chute, and sludge drainage is complete.

Application scope

It is majorly applied for solid-liquid separation of suspension liquid products; it is widely used for treating sludge caused during oily sludge treatment period; coal slime recovery in coal washing plant, dewatering of gold tailings, dewatering of alumina mine, separation and washing of hard charcoal, once sludge treatment in chemical industry, separation of xylogen in paper-making solution etc; it is also applicable for sewage treatment and solid-liquid separation in other chemical, metallurgical, pharmaceutical, light industry, coal, food, textile, environmental protection and energy industries etc.