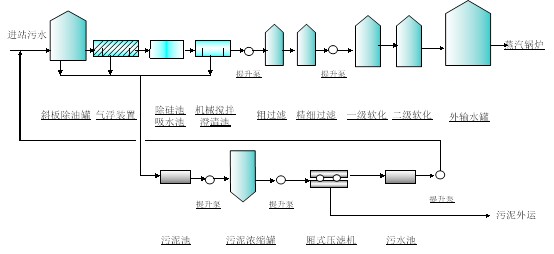

Heavy oil produced water has features of high temperature, high salt content and suspended solids and serious emulsification, except for having generality of common produced water, therefore, it is harder to treat. Heavy oil sewage advanced treatment recycling boiler technology developed by our company successfully resolves this problem. This technology has obtained 2008 country technology advancement second award. Heavy oil sewage advanced treatment recycling boiler technology adopts four key technologies and equipment of air flotation, fine filtration, softening and desilication, recovers oil, removes suspended solids, hardness and silicon dioxide to water quality standard required by gas injection boiler, and completely meets the requirements of “feedwater treatment design specifications for wet steam generator of heavy oil produced water” SY/T0027-2007 and “water quality index and water quality test method for wet steam generator of heavy oil produced water” Q/SY LH0233-2007. Air flotation unit adopts high efficiency air flotation technology and control suspended solids and oil below 20mg/L and 10mg/L separately; filtration unit adopts hyperfine filter material filtration technology and can control suspended solids below 2mg/L; softening unit can control the hardness below 0.1mg/L; desilication unit can control silicon dioxide below 100mg/L.

This technology has already been successfully applied in Liaohe oilfield and Shengli oilfield. Only Liaohe oilfield has five heavy oil sewage advanced treatment stations, with about 80000 cubic meter per day daily wastewater treatment and significant economic benefits. Taking Liaohe oilfield Lengjia sewage treatment plant as an example, its design size is to treat 15000 cubic meter crude oil produced water per day, sewage after treatment: 8000 cubic meter used for thermal recovery boiler and 7000 cubic meter used for production injection; it has been formally put into operation in 2006 and has set a precedent for domestic petroleum and petrochemical industries. Heavy oil recycling has three advantages: recovering thermal energy, reducing clean water resource consumption and invalid rejection quantity of deep well. The temperature for heavy oil sewage of Lengjia oilfield can reach up to 70~75℃. After treatment, it is reused to gas injection boiler, which can save more than 10 millions fuel cost and more than 3 millions cleaning waters. In addition, it can create nearly hundred million yuan recovery crude oil benefits from sewage every year.